The use of cork for applications other than cork is not new. In southern Spain cork buildings have been identified in a Bronze Age city. Already the Roman people used it for the covering of roofs, and to cover the helmets of the centurions. Around here, at the time of the Discoveries, many caravels and ships used a variety of cork utensils.

Due to its cellular structure, this material has a set of characteristics that make it an asset in the most diverse areas. The industrial cork products are lightweight, have great elasticity and resilience (returning to its original shape after being subjected to pressure), are impervious to both liquids and gases (and therefore does not rot), have a low conductivity of heat, sound and vibration, and are very fire resistant (does not flame or expel toxic gases during combustion).

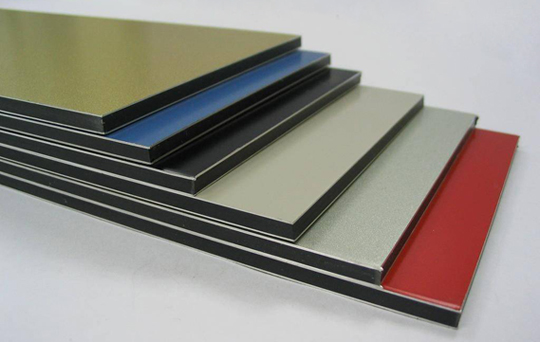

Construction is in areas where the use of cork is most common. We speak of agglomerates from the first and second bark extracted from the cork oak (which is not used for cork stoppers) and waste from the roller industry, which will give rise to boards for thermal, acoustic and vibration insulation and the coating of walls and floors.

The material also reaches areas such as music, on wind instruments; sport on hockey balls, badminton shuttlecocks, martial arts mats and bicycle handlebars; or transport, for example in engine joints and gearboxes of the automobile and in the aeronautics and aerospace industry.

For a protective effect, cork is used in front of aircraft and rockets. When they have to pass the atmosphere, they are subject to extremely demanding temperature conditions. Cork will burn like any other material, but it maintains its structure.

It is also used in rail-based structures for train weight reduction which translates into fuel savings and softening noise and vibration.